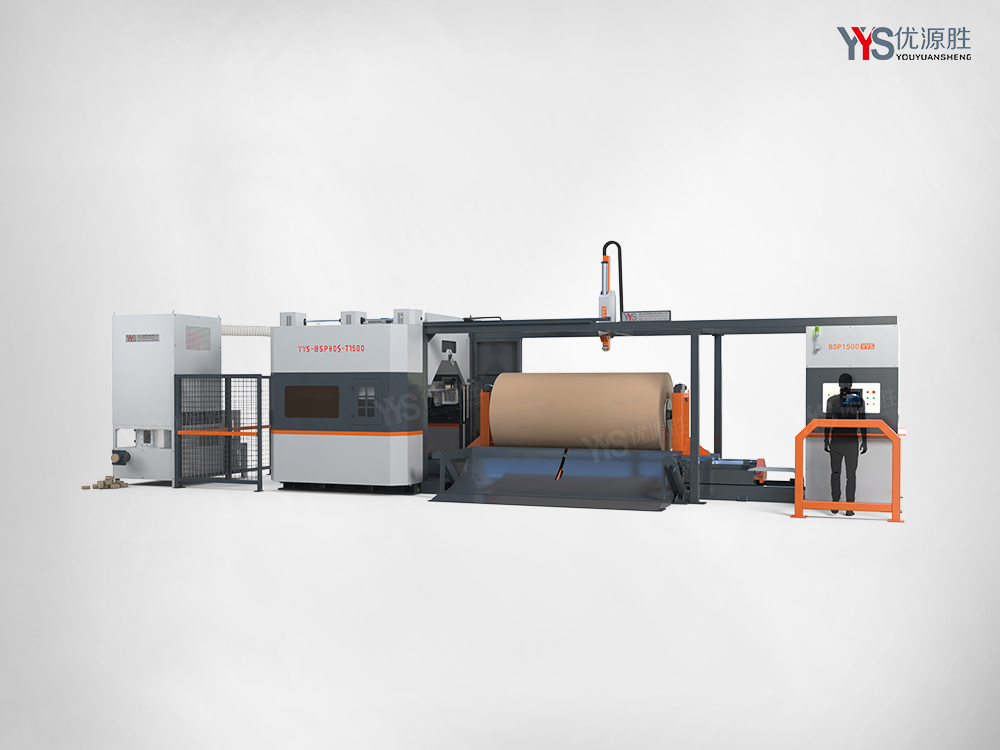

JZW-RE650A Slitting-Rewinding Machine

Home > Products > Slitting-Rewinding Machine > JZW-RE650A Slitting-Rewinding Machine

Description

Main function

Slitting and rewinding of various kinds of paper and self-adhesive label materials

Equipment introduction

Main motor: Driven by AC motor with frequency converter as the material to accelerate, decelerate and stabilize fast speed.

Rewinding drive: Two rewinding motors cooperate with the main motor to form three-motor motion control. Meanwhile the main motor separates the feeding motor, and the winding motors control the tension during operation to make finished product tension stable and appearance beautiful.

Rewinding device: The winding rocker arm adopts intermittent shifting guide wheel, which can automatically measure the diameter and shift to maintain the shortest process with the finished product. The winding method includes center and surface working, and both of them can be freely selected when rewinding different materials.

Finished product rewinding: It can be equipped with slatted air pressure shaft and slip rewinding shaft, suitable for more material range. The way of shaft change can be specially designed, and it can be replaced at any time.

Auxiliary unloading of finished products: The model is equipped with fast body rotating frame unloading, which can be completed quickly when the finished products are loaded.

Motor control: The operation interface adopts the LCD touch screen, which can directly set various winding conditions and operating conditions on the screen. The control part uses a programmable controller for mechanical action control, equipped with a self-testing system, which can diagnose the fault cause by itself when the machine errors.

Basic placing material form: Separate movable frame, equipped with automatic edge matching device to ensure stable output of waste edge, and other devices can be installed.

Auxiliary feeding of raw materials: Using hydraulic power, suitable for workshops without driving, which can save manpower and shorten loading and unloading time.

Placing material part muffler cover: Reduce the noise generated when the material is rolled out and improve the quality and safety of the working environment.

Ear material handling device: Optional independent or connected wire winding machine to pick up waste, in addition to strong windmill can be used for non-viscous materials.

Automatic line setting device: suitable for slitting after printing, which can be accurately aligned with the printing reference line for slitting.

Specifications

| Name | Size | |

| 1 |

Maximum winding diameter |

650mm |

| 2 |

Maximum feeding diameter |

1200mm |

| 3 |

Coiling core diameter |

3-6″ |

| 4 |

Minimum slitting width |

50mm |

| 5 |

Manufacturing width |

1M/1.3M/1.6M/1.8M |

| 6 |

Maximum mechanical speed |

300M/Min |

Perfectly Adapted To Your Paper Cutting Solution

No matter you are paper trader, paper mill, pacakage, printing, Machinery dealer or other related Industry, Choosing a roll paper cutting that meets your needs is critical。

We accept sample testing service, leave your information and enjoy our free testing service → Name Email Phone Message How would you like to be contacted?

E-mail

Telephone * We respect your privacy. When you submit your contact information, we agree to only contact you in accordance with our

Privacy Policy.

Submit

YYS’s Services

Fast after-sales service

7Days 24Hours online

Professional and experienced

Engineers have 8 years experience in this Industry

High quality

Machine with International brands components and precision manufacturing

Good Reputation

YYS With high-quality products, stable use of effects, perfect, meticulous, fast after-sales service won the trust of customers

Paper Trimming Machine details

Automatic online trimming machine, working together with cardboard line when cutting. Infrared positing, servo speed, automatic cruise, moving operationg,3times efficiency.

TAKE ACTION NOW

Paper Trimming Machine

Paper Trimming Machine

Paper Trimming Machine

Paper Trimming Machine

Paper Trimming Machine Sourcing Paper Cutting Machine From YYS

Boost Your Business

For Factory Owners

We have worked with different companies to take their ideas from conception to realisation of their efficiency and cutting paper solutions. Whether it’s a customised function or a customised look, we can provide you with the perfect Post-press processing solutions.

For Distributors

Our modern production plant allows us to offer great quality options to appeal to your target customers. As a distributor you can trust that our streamlined manufacturing processes are here to provide you with the best machine in the market.

For National Agents

Being one of the most paper cutting Machine manufacturing companies, we offer the best quality products at a significantly low cost. This allows us to work with you to ensure that you get to also extend great prices to your customers.

Why Choose YYS

At YYS, our mission is to be globally competitive in a highly volatile market. Our goal is to be the global supplier of choice for blanking machines. Through innovation, we can provide better products to our customers. We help more factories to further improve productivity, reduce labor costs and meet production demands.

Installation, Parts & Service

Equipment is only valuable to you if it works

That’s the reason you count on durability and longevity in your recycling equipment investment. Why choose YYS? One simple reason…because We Get That. We understand how critical your equipment is to your business. YYS works hard to exceed your expectations and to make it easy for you to do business with us. When you call YYS for help, our goal is to be focused 100% on helping you get what you need.

We know you are not an equipment expert. That’s why we are here.

Our specialized services are tailored to meet your specifications and on-site requirements. YYS’s specially outfitted fleet enables ready and comprehensive customer care.

All of our equipment is backed by the ongoing maintenance and support of over 100 combined years of industry experience making us able to offer service you can trust from people you know.

Installation

- Full service project management of the installation of your equipment

- Online logistics planning and project tracking

- System start-up and training by factory trained technicians.

Parts

- Fully stocked inventory gets service or replacement parts to you quickly

- Parts can be ordered via phone, email or online

- Wide selection of baling wire in all types and sizes for a variety or machines and applications

Service

- Full in-house and off-site service capabilities with a fully maintained fleet of service vehicles – Our experienced technical team can service or rebuild equipment at our facility or on your site

- Technical assistance available via phone and web conferencing

- Mobile PLC diagnostics and repairs

Our Factory View

Our Certificate

Ordering From Us

The new purchase and delivery of a Paper cutting Machine can be stressful and time-consuming. Importing can be confusing when one is not familiar with the transaction process. Here are few simple steps on how to order our machines.

Step 1

Confirm Equipment Solution (3-7 days)

It’s important to know what kind of paper you cut, and what’s your paper size, what’s problem you want to solve before you order. But if you don’t know, don’t worry! Our colleagues will help you! Good service is a good beginning of the order.

Step 2

Step 2

Machine Production (20-30 days)

Customers pay the deposit, we will arrange the production within 1 day. Our approval process is efficient and fast to maximize the time and cost savings for our customers.

Step 3

Shipping (15-40 days)

There are different shipping ways for options. Air shipping is fast but expensive,it’s a good choice for urgent orders, it onlytakes10-15 days max. Sea shipping is the most economical shipping way, time is much longer than air, takes 20-40 days.

Step 4

Step 4

Installation and Commissioning (1-5 days)

Our installation services can help you tackle a variety of projects, whether you choose Band saw paper cutting machine, Paper Roll saw cutter or other equipments. We will supply you Install drawings, videos etc, and also can arrange engineer to visit when needed.

Step 5

After Service

At every stage of machinery project, our customer service department will be there for you.

Our team is available to assist you with day-to-day tasks such as machine installation, spare parts delivery, commissioning, and maintenance.

Our experts are easy to reach, responsive, and enthusiastic about their work, so you can rest assured that you will be satisfied!

For a worry-free project, contact us today!

FAQ

Number One commits to providing you professional service, quality products at a competitive price.

Product

What kind of rolls paper you machine can cut? Kraft paper, corrugated paper, woodfree, etc

What is the difference between your machine and slitting rewinding?

Our machine can cut broken paper, modify the size of the width, and work efficiently, but cannot change the diameter. The rewinder can modify the width and diameter of the Roll paper, but it cannot function properly when damaged paper.

What is space for machine place?

The band saw is about 70 square meters (9 meters long and 8 meters wide), and the Roll paper saw is about 20 square meters

How about cutting surface? How much paper loss?

The cutting surface is very smooth, band saw loss of paper about 2MM and Roll paper saw about 10MM

It can cut around 1500 rolls for one blade, but should sharpen the blade after cutting 300-500 rolls depends on the kind of roll paper

Can supply installation service?

We provide installation information and video, remote guidance. If required to install on site, round-trip air tickets, board and lodging, and workers salary 300USD per day are required.

Regular

We accept EXW price term, but you should export by yourself

We prefer to T/T, 30% as deposit , 70% balance before loading.

30% prepayment, 60% before delivery, 10% after one month of installation and commissioning.

Yes, we accept L/C, we will need 30% deposit by T/T, and the balance by L/C at sight . Firstly

Generally speaking, we recommend using TT for first-time cooperation. If LC is a must, 30% deposit TT + balance LC at sight is requested. We don’t recommend doing DP.

Sorry We need a 30% deposit. and 70% balance before loading.

Delivery time

For Roll paper saw around 20days, and band saw blade around 40-60 days

We have checked with our production department, our supplier delayed for the raw Material we will give you some discount for next Order

Quality

Yes, we have 1 year warranty, but except

How about the quality of your products?

You can rest assured about the quality. Reliability is our strong point.

Our products are using environmental & friendly ABS material. Pass a full set of safety certification.

Price

Can you accept price without TAX?

As our company is a high-tech enterprise, we can only offer tax inclusive price.

Several types of paper cutting machines in facyory. Is your company a paper trade or a cardboard factory? Equipment should be recommended according to paper material and specifications.

We will give best price according to payment and distance after checking which Model will availablefor you

Advantage

We export paper cutting machine for more than 6 years and cooperate with many paper factory in the world. We also protect our customer profit and have a professioan QC team to check the quality before we ship the goods.

Your competitor’s products are so cheap. Why are you so expensive?

The product design is different, the material is different, the price will be different, the weight of the equipment is more than 2 times in the peer equipment.

May I know what the certificate of this product is?

Sure, Our products all have ISO and CE Certification

We Mainly selling products as Saw blade cutting Machine, Band saw paper cutting machine and saw dust Baler

We did investigate the market recently and have some new products to share with you.

Do you have agency in European?

Yes, you can talk with them for details

Related Products

JZW-RE1200 Slitting-Rewinding Machine

JZW-RE650A Slitting-Rewinding Machine

Automatic Slitting Machine

Roll Slitting Machine

Thermal Paper Slitting Machine

Rubber Slitter